Umatshini osisigxina weMagnet ye-Synhronous Gearless Traction THY-TM-K300

| I-Voltage | 380V |

| Ukurhweba | 2:1/4:1 |

| Iqhoboshi | DC110V 2×1.6A |

| Ubunzima | 520kg |

| Umthwalo omkhulu | 6000kg |

1.Ukuhanjiswa ngokukhawuleza

2.Intengiselwano sisiqalo nje, inkonzo ayipheli

3.Udidi:Umatshini wokutsala THY-TM-K300

I-4.Sinokubonelela ngoomatshini be-synchronous kunye ne-asynchronous traction ye-TORINDRIVE, MONADRIVE, MONTANARI, FAXI, SYLG kunye nezinye iimpawu.

5.Ithemba lulonwabo! Andisoze ndilahle ithemba lakho!

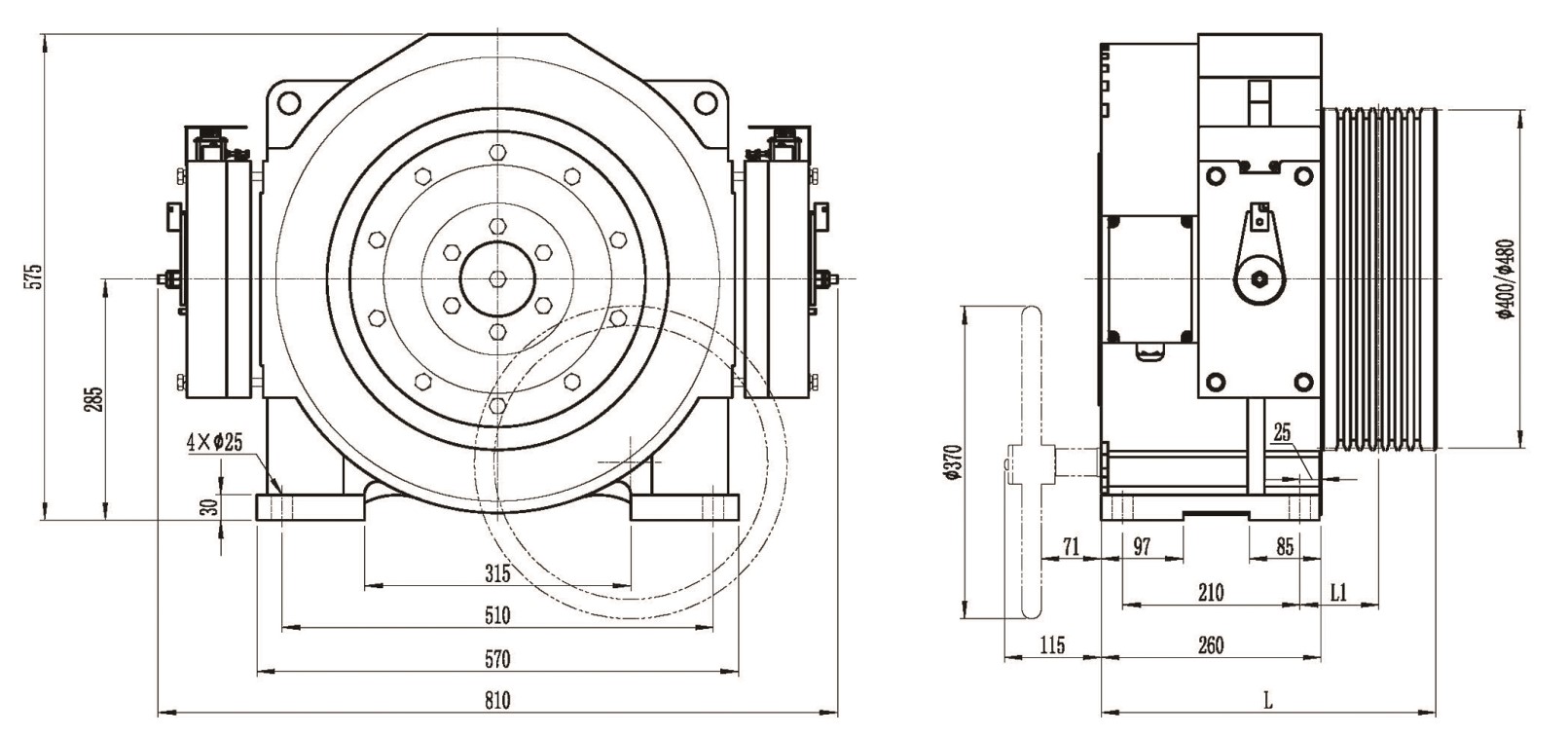

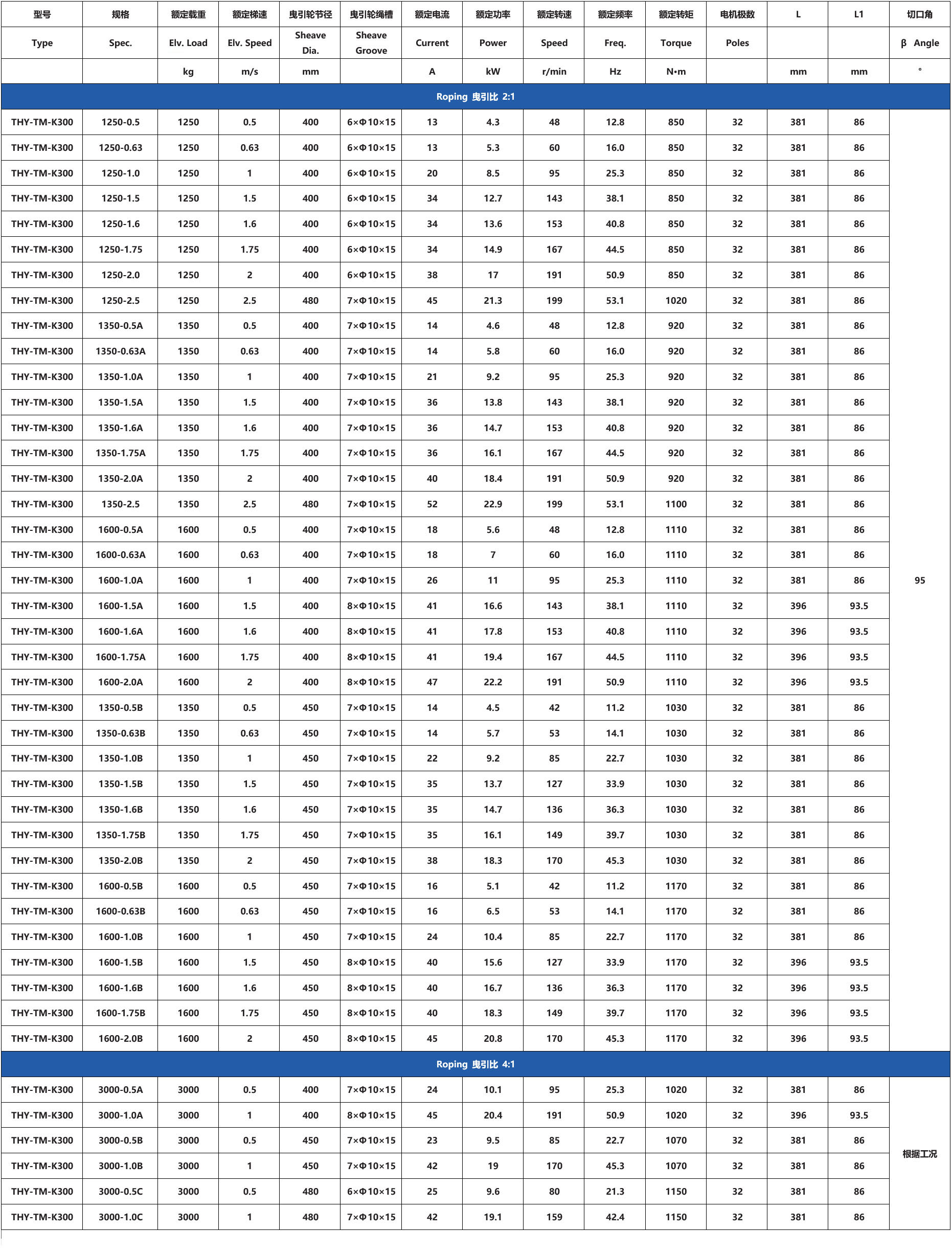

Uyilo kunye nokuveliswa kwe-THY-TM-K300 yemagnethi esisigxina ye-synchronous gearless elevator traction machine ihambelana ne-"GB7588-2003-Safety Code for Elevator Production and Installation", "EN81-1: 1998-Imithetho yoKhuseleko yoLwakhiwo lwe-Elevator kunye noFakelo", "204 Imimiselo ye-Traction-E8 ye-Tr. Uyilo lobomi obuthwele umatshini wokutsala ufezekise iimfuno zokusebenza Emva kwexesha lokusebenza (unyaka we-1 okanye njengoko kufuneka), igrisi idinga ukufakwa, kwaye akukho mfuneko yokongeza okanye ukubuyisela igrisi kwiibheringi ezitywiniweyo, nceda ulandele iimfuno ze-injection ngale ndlela ilandelayo: Nceda ujove i-Mobil Grease XHP222 (NLGI umhla we-201 ye-injini ye-201) (V220C 2 grade) kwi-injini ephambili kunye nomhla wemveliso emva ko-2018. Ifanelekile kwi-elevator enegumbi lomatshini kunye ne-elevator ngaphandle kwegumbi lomatshini Umlinganiselo wokutsalwa ngu-2: 1 kunye no-4: 1, umthwalo olinganisiweyo ngu-1250KG~1600KG, isantya esilinganisiweyo yi-0.5~000mm, i-2. I-450mm kunye ne-480mm Ifanelekile indawo yokusebenza yangaphakathi.

• Lungisa isithuba sebrake (umgama phakathi kwepleyiti engatshintshiyo kunye nepleyiti eshukumayo), isithuba sebrake singaphantsi kwe-0.1mm xa sisebenza, kwaye simalunga ne-0.25~0.4mm xa sikhutshwa.

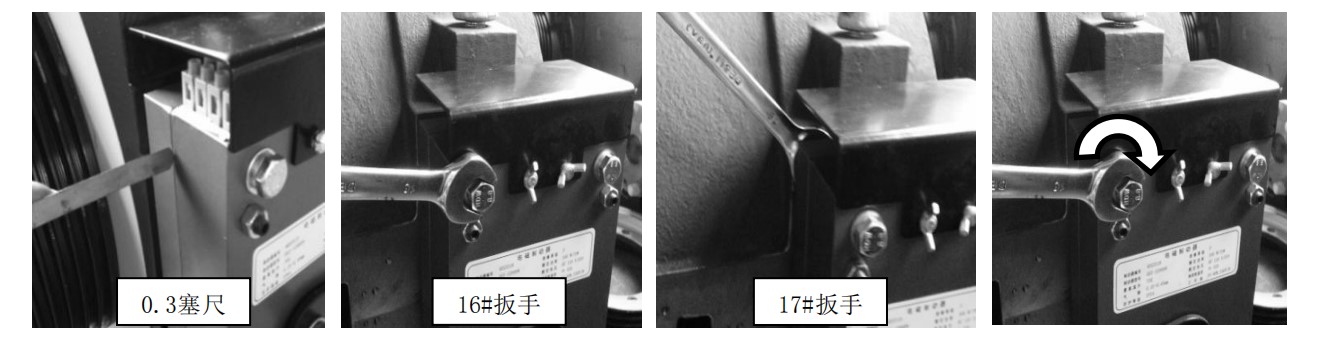

• Sebenzisa igeyiji ye-0.3 ye- feeler gauge ukujonga isithuba somoya kwikona ye-brake: xa isithuba somoya singaphantsi kwe-0.3mm, khulula ibholithi yokunyusela kule kona ngokunxamnye newotshi, emva koko ujike ibholithi eholoholo ngasekunene kwewotshi kwi-engile encinci, uze emva koko uqinise ibholithi yokunyuka.

• Sebenzisa i-0.35mm yegeyiji yokukhupha umoya ukujonga umsantsa womoya we-angular: xa umsantsa womoya ungaphezulu kwe-0.35mm, khulula ibholithi exhomayo ekoneni ngokunxamnye newotshi, emva koko ujike ibholithi eholoholo ichasene newotshi kwi-engile encinci, uze uqinise ibholithi yokunyusela.

• Lungisa isithuba seekona zonke zebrake ukuqinisekisa ukuba i-0.3mm yegeyiji yokuvalela inokudlula, kunye ne-0.35mm yegeyiji yokuvalela ayinakudlula.

•Xa isiqhoboshi sibambene, sebenzisa i-0.08mm feeler gauge ukujonga ukucoleka kwevili phakathi kwevili lebrekeki kunye nebhrekeki pad. Xa ucoceko lungaphantsi kwe-0.08mm, phinda indlela yohlengahlengiso lwe-brake clearance, kwaye lungisa kakuhle ukuqinisekisa ukuba ukukhutshwa kwevili ngu-≥0.08mm.

• Susa isiciko esiphezulu se-brake kwaye ulungise ibhloko yokulungiswa kwe-micro switch ukwenzela ukuba xa i-brake ivuliwe / ivaliwe, i-micro switch inokuvulwa ngokuthembekileyo / ivaliwe, kwaye ikhava iphinda ifakwe emva kokulungiswa.

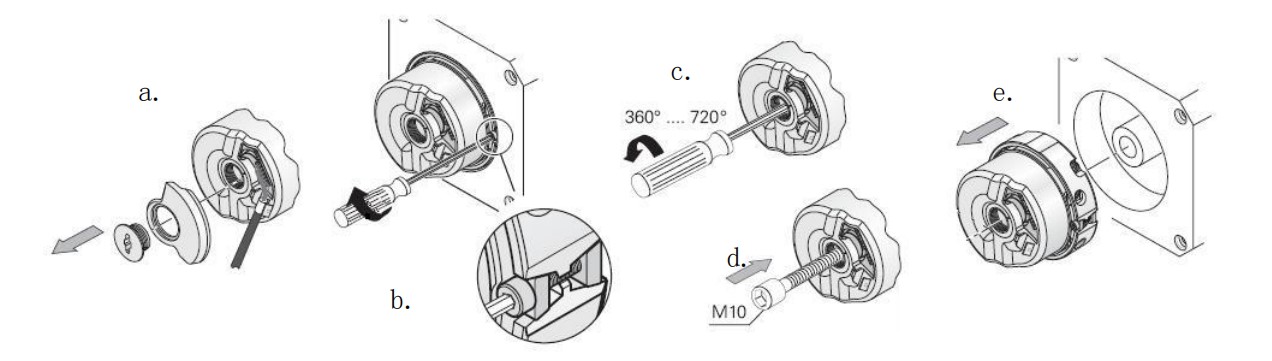

a. Sebenzisa isitshixo sika-Allen esiyi-3mm ukususa isigqubuthelo esingasemva sothuli se-encoder.

b. Khulula isikrufu sokwandiswa kweringi yangaphandle ye-encoder ngeqhosha le-2mm Allen.

c. Khulula isikrufu se-M5 (2~4 ujiko) ukuze uqinise i-encoder ngeqhosha le-4mm Allen.

d. Sebenzisa isitshixo sika-Allen esiyi-8mm ukujija isikrufu se-M10 ukutyhala ngaphandle isikhowuda.

e. Bamba i-encoder ngesandla sakho kwaye uyisuse ngobunono kwaye uyibeke kwindawo ekhuselekileyo.

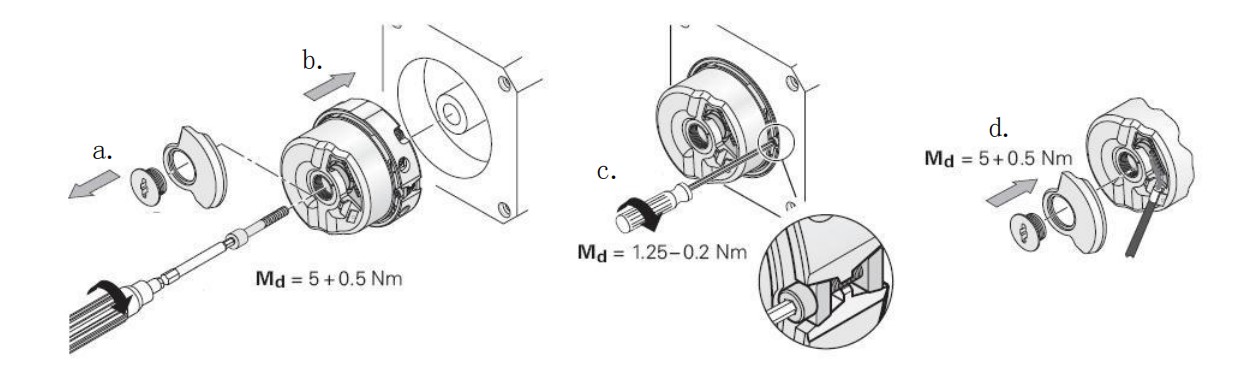

a. Sebenzisa isitshixo sika-Allen esiyi-3mm ukususa isigqubuthelo esingasemva sothuli se-encoder.

b. Qinisa i-encoder M5 mounting screw (ukuqinisa amandla 5+0.5Nm) ngeqhosha le-4mm Allen.

c. Sebenzisa isitshixo se-2mm Allen ukuqinisa isikrufu sokwandiswa kweringi yangaphandle ye-encoder (amandla okutshixa 1.25-0.2Nm).

d. Sebenzisa isitshixo se-Allen esiyi-3mm ukuqinisa isigqubuthelo esingasemva sothuli se-encoder (amandla okutshixa 5+0.5Nm).